The world around plastic cups

By Steffen Andersen · 17. April 2020

One of the materials that are really discussed when it comes to packaging is plastic.

Because of that, there are a lot of beliefs about whether plastic is good or bad for the environment and how sustainable the material is.

We at Limepack offer a couple of different plastic packaging solutions since it is one of the most durable materials that exist.

That of course also makes us a bit biased in terms of plastic and the pros and cons of it. In this post, we have tried to gather all the different questions related to plastic cups.

So we will both go through how plastic and plastic cups are made, the different types of plastic and in the end, we will talk about their lifecycle.

How is plastic made?

The way plastic is made depends a lot on which type of plastic there is used for the plastic cups.

So let’s start with going through the three different types of plastic that is used for making plastic cups.

The kind of plastic there is used for making the plastic cups do also have a large influence on their impact on the environment(We will go into depth with the environmental impact later).

The three different types of plastic is PET, rPET and PLA plastic.

PET plastic

PET stands for polyethylene terephthalate, which is the most common type of plastic.

It is especially used for bottles and more flexible plastic materials since it is really durable, and if it is collected correctly it can be recycled and used for other rPET.

It also the most used material for making plastic cups because there is a large supply of it, and it is approved to be in contact with food materials.

The plastic is made from Naphtha oil which is a fraction of raw oil, this is made during a refining process where the oil splits into Naphtha, Hydrogen and other fractions.

The oil extract Naphtha then become plastic via a process called Polymerization. The process connects ethylene and propylene to form polymer chains which in the end is what PET plastic is made of.

rPET plastic

rPET stands for recycled polyethylene terephthalate, and it is the most commonly used type of recycled♻️ plastic, because the durability of PET makes is easy to recycle and still ensure a high quality.

Recycled PET is becoming a more widely used kind of plastic general, and a lot more companies are trying to make their products from rPET instead of normal PET.

This is especially the construction industry, where more windows are made from rPET plastic. It could actually also be the frame for glasses.

When the PET material has been sorted, the materials are grounded into particles known as plastic flakes, a bit like paper pulp.

The purity and how well these plastic flakes are perved, and how well they are washed and rinsed from bacteria will determine the quality of the recycled plastic.

Before the materials are dried and made ready to use in the production of other materials, it goes through a process to remove non-melt contaminants.

PLA plastic

PLA is short for PolyLacticAcid, which is a kind of bio-plastic. It is the most widely used bio-plastic in the world.

PLA plastic is widely used as a material for both packaging, construction, and other products due to it being called bio-plastic.

We will dig into later on how environmentally friendly it is. We can as an example both make paper cups and plastic cups in PLA plastic.

One of the main problems with PLA plastic is that supply is a lot lower than the demand for it, why the prices for it are a lot higher than PET and rPET plastic.

PLA plastic is a polyester produced by plant-based materials such as corn starch or sugar cane. When using this to produce PLA plastic there a couple of steps.

The materials used go through wet milling, where the starch gets separated from the rest of the materials that are extracted from the plant material.

The starch is then mixed with acid or enzymes and finally heated. The corn starch will become D-glucose, and it then goes through a fermentation process which will turn it into Lactic Acid.

How are plastic cups made

When it comes to plastic cups and how plastic cups are made it actually makes a difference if it is disposable or reusable plastic cups.

You might also know reusable plastic cups as hard plastic cups. The type of plastic cup does not only influences how they have produced but also their environmental effects and what they are normally used for.

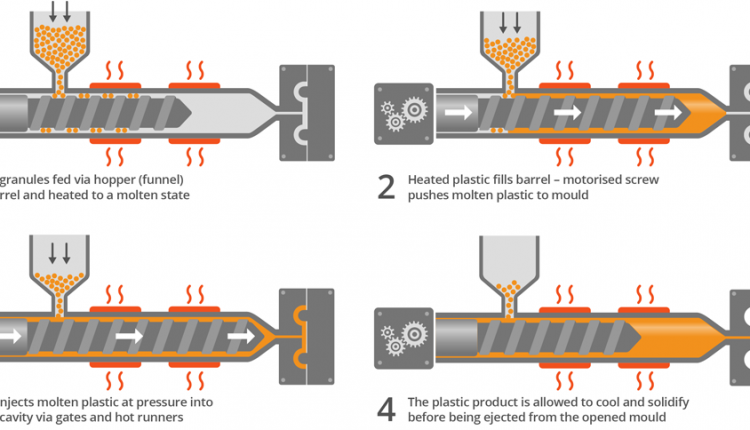

The plastic cups are made through a process called injection molding, where the plastic materials are mixed with liquids and inserted into the template for plastic cups, that determines the size and thickness of the cups.

The injection molding process starts with the raw material being put into a machine called a hopper.

The machine actually just consistently mixes the kind of plastic with other materials needed to form the end resulted. When the materials have been mixed in will be poured into the templates and when it has the right thickness and size it will stay in the template and cool of.

The only ling lefts are for the plastic cups to be slowly heated to remove the cast from the surface.

So what influences if the plastic cups are made as a disposable or reusable one depends on the templates the manufacturer uses.

This is actually still a rather big set-up for the manufacturer, which is also the reason why manufacturers specialised in either making disposable plastic cups or reusable plastic cups.

Printing on plastic cups

To-go drinks are becoming a more influential part of our lives, and it is also becoming a part of many more cafes, juice bars, and etc. selection.

Why it is also important for the small juice bar to differentiate from the rest of the competitors. Printing on plastic cups is a great way to do that, it might actually also be the easiest one because the juice bar already needs the plastic cups for selling them to-go.

We help a lot of customers get print on their plastic cups, and we work with a couple of manufacturers who have different printing methods for the plastic cups – We will go through the different printing methods on plastic cups, they are flexo-print, offset print, tampon print, and digital print.

Tampon print

Tampon printing is the most used printing method for plastic and especially plastic cups in smaller quantities, that is because of tampon print being really good for printing on convex surfaces.

The Tampon printing method works as a stamping effect, where the ink is taken directly from the printing plate and placed onto a flexible silicone pad and later stamped onto the plastic cups to be the print.

The reason why Tampon print is not widely spread in other categories is that it’s difficult to make a print that covers the whole surface, and is best for making a print on each side of the cup.

Flexo-print

Flexographic printing is mostly used for printing on the surface of convex plastic packaging in large quantities.

This is due to the high cost of the printing plate and setting up the printing plates because you need a printing plate for each colour.

The flexographic printing method works with rollers that are rolled directly onto the plastic cup to put on the print, to ensure a faster and cheaper printing method.

The printing plates are made of plastic, why they can be used to print many cups before needing to be changed.

Offset printing

Offset printing is the most used printing method when it comes to printing large quantities.

The printing method is especially used for magazines, newspapers, and products that need the same printed on it in a high volume.

The offset printing technology uses printing plates made of aluminum that then transfers the print onto a rubber “blanket” that rolls the print onto the product.

It is called offset because the printing plates do not directly print the product, but a roll does instead.

Offset printing is probably the most efficient printing method, but it actually also give the most accurate colour reproduction.

Which is also why more plastic cup manufacturers choose this printing method since the print is accurate on convex surfaces and the transparent background.

Digital print

When it comes to plastic cups, we do not have the knowledge or been able to research us to the knowledge of people who could make digital printed plastic cups.

It is mainly because Digital Printing as a method uses CMYK-colours, and the technology for printing CMYK colours on plastic cups are not available today.

If digital printing were able for plastic cups, it would help make the minimum order quantity become lower and the start-up cost as well, because the cost of a printing plate is next to zero.

Colours used on plastic cups

Printing on plastic cups does of course also require some colours that can be printed on plastic cups.

So in the following will talk a bit about Pantone colours used on plastic cups.

You might be wondering why cannot print it with CMYK colours, but the simple answer is that the way the colour scheme work it cannot be printing on plastic cups with the current technology.

Pantone colours

The reason why Pantone colours are the only colour scheme that can be printed on plastic cups is that Pantone colours are not mixed when the print is put on.

Since the Pantone colour scheme consists of 1867 specific colours, the colours are added directly in the area where they are needed in the print.

The reason why it is important that the colours are not mixed when added onto the print is that the plastic cups are transparent and if the colours are mixed they will become unclear.

This is also the reason why when buying plastic cup that you have to pay extra for each colour you add in your design.

How are plastic cups transported?

One of the most important things when buying plastic cups, and measuring the environmental impacts of plastic cups, is the delivery of the plastic cups and how they are transported.

The plastic cups can be transported in multiple ways, and the transportation method often depends on how much in a hurry the customer is.

Plastic cups are normally transported with a truck or cargo ship depending on where they are produced.

Some packaging is also sent with a plane to be able to reach a deadline, and as cargo planes are very common you can ship something across the world in one day.

We do not know of any plastic cup producers that send their plastic cups with a plane.

We do therefore not go more into depth with the co2 emission of transporting plastic cups with a plane.

What is worth noting is that the co2 emission is 2 to 3 times higher when transporting something a plan than with truck, and 11-15 times as higher than with ship.

Just to illustrate it, below I have shown how much CO2 from the different transportation methods. The metric is grams per ton of freight and per km of transportation.

- Airplane (average cargo B747) – 500g

- Lorry or Truck – 60g to 150g

- Train – 30g to 100g

- Ship – 10g to 40g

Whether the plastic cups are sent with cargo truck or ship normally depend on if the plastic cups are produced in Asia or in Europe.

So let use as an example that we should deliver some plastic cups in Germany, and we have one manufacturer in China and another manufacturer in Greek.

The distance from Hong Kong to Port of Hamburg is 22737 kilometers with ship, where the distance from the middle of Greek to Port of Hamburg 2502 kilometers.

To make this calculation we would have to take the amount of the distance the truck or ship has traveled, the weight of the shipment and the mode’s specific emissions factor.

Let’s say the plastic cups weigh 1 ton since it is an easy number to use.

We would then Multiply the 2502 kilometers with 1 ton, and that would be 2502 ton-kilometers.

Hereafter we would have to multiply the emission factor with the ton-miles and let’s say the truck emits 90 kilograms of co2 pr. ton-kilometer. (90 x 2502) which is then 225.180 grams of co2 for the transportation of 1-ton plastic cups with a truck.

- Ship for the 22737 kilometers is 0,568 tons of co2

- Truck for the 2505 kilometers is 0,225 tons of co2

Due to the long distance that the ship had to cover it releases more co2 during transportation, but if it was 40% of the distance, it would not emit more co2 under transportation.

Most of all plastic cups are though produced in Asia and sent with a ship to Europe. We do though experience that more and more choose European production due to the lower delivery times.

What are plastic cups used for?

As I have already covered there are two different types of plastic cups, when it comes to being used for to-go drinks. It is reusable plastic cups or disposable plastic cups.

The two different types of plastic cups are normally used in different settings.

Disposable plastic cups

The disposable plastic cups are normally used at open events where people can sit around with their friends. The disposable plastic cups are of course primarilly used for to-go drinks from a café, juice-bar or a milkshake from the local ice bar.

Plastic cups are transparent which makes it easy to show the drink inside, and they are really durable so they can be used to both alcoholic and non-alcoholic drinks.

Disposable plastic cups can sometimes also end up competing with reusable plastic cups, in what the event organisers should use a cup for the drinks.

This is especially the case at festivals and 2-day events, where the attendees could be really bad at reusing the plastic cups and it would, therefore, be more beneficial to use disposable plastic cups.

Reusable plastic cups

The reusable plastic cups can come in two different types. One of the types is used for soft drinks and alcoholic drinks, it is because they are a bit of transparent.

The other types are used for hot drinks such as coffee and tea because some are made with a sleeve that protects the customers from burning their hands.

The transparent reusable plastic cups are mostly used in closed communities, this could be an entertainment park where the different shops have to use the same reusable plastic cups and it, will in that way be easy to collect, wash and reuse.

The reusable plastic coffee cups are also primarily used in closed communities, but more often at fairs and professional indoor events.

They are actually also used by many consumers to bring their morning coffee to the office since you can get a lid for the cups.

Some larger offices do also have reusable plastic coffee cups because the employees move a lot from different sections and would like to bring their coffee with them.

What is more environmentally friendly?

When talking about environmentally friendly products, and ensuring that products are becoming more environmentally.

The focus is often on how the products are decomposed or can be recycled, often we forget the consequences and emission of co2 during the production of the products.

In this section we will try to cover the co2 emitted from reusable and disposable plastic cups under production, and what this means for their environmental friendliness.

In the articles that we found, about this area we only found an article that compares disposable cups in foam and paper as a material, they compare it with reusable cups made from plastic and ceramic.

Since the research does not compare disposable plastic cups and reusable plastic cups, then to find the closest result we use disposable cups in foam material as the disposable cup to compare with reusable plastic cups.

This is because the co2 emitted during the production of disposable foam cups and disposable plastic cups almost match each other.

The research concludes that if we both take co2 emitted during the production and during their life-time(washing the reusable cups) into consideration, then reusable plastic cups have to be used 30 times for the emitted co2 being the same as with disposable plastic cups.

(REF) The conclusion will then be that, whether a plastic cup or reusable plastic cup is the most sustainable plastic cups, depends on how many times the reusable plastic cups, in reality, is reused.

In Denmark, the entertainment park Tivoli, says that their reusable plastic cups are on average reused 6 times, which is a closed park.

How are the plastic cups degradable?

How and whether plastic cups do as with a lot of other things in this post depends on which materials the plastic cups are made in.

The difference is though only between PLA and PET plastic since rPET is made from the same materials as PET but it is just recycled. So we will below split it up to these two categories.

PET and rPET

Unfortunately, PET and rPET is not able to degrade in nature, as well it cannot degrade in commercial degrade machines.

Why it is so important for plastic to be collected and thrown out, if possible it should be collected and sent to recycling.

Mostly when plastic is thrown out it will be be sent to energy companies, where it can be burned as bio-fuel.

PLA

PLA is as PET and rPET not degradable in nature, why calling PLA plastic cups biodegradable is a bit of a stretch.

But PLA plastic is degradable in special industrial facilities, and the PLA plastic can only be degraded in these facilities because they need to be kept at a certain temperature mixed with some chemicals for at least 60 days, and then they will start to degrade.

It is therefore super important the PLA plastic cups are gathered and sent to correct facilities, so they can be degraded.

There are though two problems with it, these industrial facilities to degrade the PLA plastic are not that common and mostly spread in the UK.

The other problem is that the sorting facilities are not able to tell if the plastic cups are made of PLA and PET plastic, and if PET plastic goes into the same machines as PLA plastic, it can destroy the whole degrading process. (REF)

How about recyclability?

The perfect way for making plastic cups and plastic materials more environmentally friendly is by making sure that the plastic is recycled, and made into new products.

It both ensures that there are not used more oil in the production, but reused it again. This will also ensure that there is emitted less co2 under the production of plastic because we do not need to get the oil up from the ground.

The recyclability of the materials depends on which material the plastic cups are made from.

You will quickly notice that there are a lot of similarities between the different materials, both in terms of how it is recyclable but also what makes it difficult to recycle.

PET

As you might already have guessed in terms of PET plastic, it is recyclable. There are though a couple of cases where PET plastic is harder to recycle.

It is especially if the plastic is used for food packaging because the recycling process for materials that have been in contact with food is different than if it used for other purposes such as construction work.

The PET plastic from food materials will normally end up with the rest of the PET plastic, the recyclability of PET plastic is depending on how well the garbage sorting system is working in the country.

The best way to ensure that more PET plastic is recycled is that making it possible to sort PET plastic that has been in contact with food in the bin, and the rest in another.

This would ensure that all the PET plastic is sent to the correct recycling facilities, so nothing has to be sent to be burnt unless if the country does not have facilities for recycling.

rPET

When it comes to degradability of rPET plastic it actually the same as with PET plastic, but rPET plastic can only in recycled around 9 times.

When the rPET plastic has been recycled more than 9 times the quality of the plastic will not be high enough, and manufacturers of plastic products do not want to offer products of this quality.

PLA

PLA plastic is able to be recycled as with PET plastic, there is though a couple of problems that might complicate the recycling process for PLA plastic.

The first thing is that since PLA plastic is not as a durable material as PET plastic the end material of recycled PLA plastic does not have a very high demand among manufacturers.

The second thing is that PLA plastic cannot be recycled in the same process as with PET plastic, due to the recycling process of PET plastic would actually destroy the enzymes in PLA plastic, so it would not be able to be formed into products. (REF)

The way to get more PLA plastic recycled is by setting up an easier sorting system, and ensuring that the different plastic materials are sent to the correct recycling facilities.

What are the new innovations?

Innovations within the plastic cup industry are primarily within the environmental impact of them.

Which makes sense since the demands for the size, quality, and minimum order quantity of the plastic cups are not changing amongst the consumers.

rPET plastic cups

rPET plastic as a material for food packaging is not widely spread which is primarily due to the material have been difficult to get to match the requirements of food contact materials.

But because of better cleaning processes and removing former chemicals, some plastic cups manufacturers are slowly getting approved to use rPET plastic in their production.

We know of one manufacturer in the EU, who have been approved to use rPET in their production of plastic cups, why their plastic cups are made of 50% recycled plastic.

They do offer the possibility of getting 100% recycled plastic as the material, but due to the quality of the plastic, they have a high minimum order quantity for it.

The other major innovation within plastic cups is actually not about sustainability, but about the printing methods for them.

Many manufacturers are trying to make their production be able to print with offset print instead of Flexo- or Tampon, due to the higher quality of the print on the plastic cups and lower handling cost.

The last innovation that we know some plastic manufacturers are working on, and will be working on for the next many years, is how to plastic decompose in nature.

We are not aware of any manufacturers of plastic that are close to cracking the code, but we do know that they are working on it. But you shouldn’t get your hopes up to high for the time being.

Our suggestions for innovations

As we discovered in just the earlier section, the main new innovations within plastic cups and plastic food packaging are using 100% recycled plastic.

We think this is a great initiative, and we going to push our manufacturers to work harder for making this possible.

We do though think that one of the most important things to focus on, is actually on a governmental level.

Since the plastic cups can not decompose in nature or at landfills, the best thing to do for the environment in regards to plastic cups would be a better collecting and sorting system.

If the governments had this it could focus its efforts on sending plastic packaging that can be recycled to recycling facilities and plastic packaging that cannot be recycled, should be sent to plants where it can burn as bio-fuel.

We also believe an additional initiative to enhance the sorting process would be beneficial.

We would suggest making a label that all plastic cups should have marked on them, the label should not wary for each country, so companies are able to streamline the process no matter where the plastic cups are used.

The label should specify what type of plastic the cups are made from.

There should be a label l for PLA plastic cups, and another one for PET plastic cups and a third for rPET plastic cups.

This would especially help with getting more plastic cups recycled since they would be sent to correct recycling centers.